This article now takes a different role from the first comparison piece.

Instead of asking which material is better, the real question here is:

Why do so many TPE cock sleeves feel different after weeks or months of use?

The answer lies not in poor manufacturing, but in how TPE behaves under real-world conditions.

What Users Often Notice First

Most changes don’t happen suddenly. They appear gradually and are easy to dismiss at first.

Common observations include:

- A surface that feels tacky or greasy

- A subtle but persistent odor

- Reduced tightness or support

- Texture that feels less defined

These are not isolated complaints — they follow predictable patterns tied to material behavior.

Cock Sleeves Are a High-Stress Use Case

Compared to many other adult products, cock sleeves place unique demands on their material:

- Continuous stretching and compression

- Prolonged skin contact

- Heat buildup during use

- Frequent washing and drying

TPE can handle these conditions temporarily, but it is not optimized for repeated long-term stress.

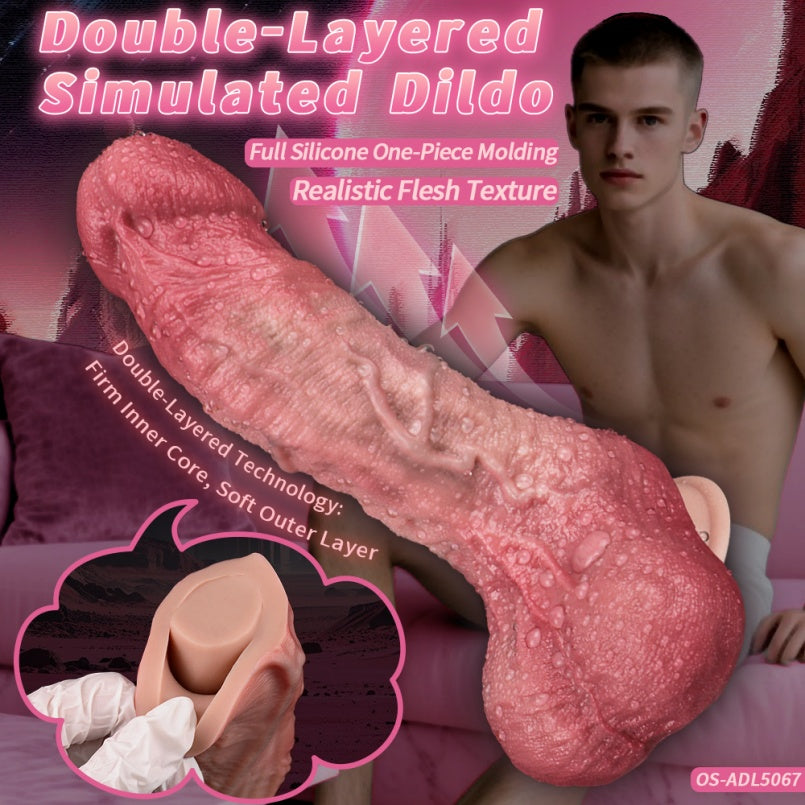

Compared with TPE sleeves, silicone cock sleeves provide noticeably better elasticity, a softer feel, and a more refined texture, while remaining durable and resistant to cracking even under repeated stretching.

The Science Behind Oil Migration in TPE

TPE is a blended material that relies on plasticizing oils to achieve its softness.

Under mechanical stress — such as stretching or compression — these oils are gradually pushed toward the surface. Heat and cleaning accelerate the process.

Once the oils migrate outward, two things happen:

- The surface begins to feel greasy or sticky

- The internal structure loses some of its original elasticity

This process is irreversible. Washing can remove surface residue, but it cannot restore the material’s internal balance.

Why Cleaning Can’t Fully Fix TPE Degradation

Regular cleaning is essential for hygiene, but it cannot reverse material fatigue.

As TPE ages:

- Surface oils reappear after drying

- Porosity allows residues and odors to remain trapped

- Strong cleaners may further accelerate drying

What many users interpret as “wear and tear” is actually material breakdown at the molecular level.

Elasticity Loss and Fit Changes Over Time

Cock sleeves rely on elastic rebound to provide consistent pressure and sensation.

As TPE loses internal oils, its ability to return to its original shape diminishes. This often results in:

- A looser fit

- Reduced support

- Less predictable performance

For sleeves designed to enhance size or fullness, this change becomes particularly noticeable.

Why This Matters More for Cock Sleeves Than Other Toys

Not all adult products stress materials in the same way.

Cock sleeves are uniquely demanding because they combine:

- High stretch ratios

- Internal pressure

- Long session durations

In these conditions, material stability directly affects comfort, sensation, and lifespan. What works for a simple molded toy may not perform the same way when pushed to these limits.

Why Silicone Ages Differently

Silicone does not rely on added oils to remain soft.

Its elasticity comes from a stable molecular structure that resists migration, drying, and deformation. Even after extensive use, high-quality silicone maintains:

- Surface consistency

- Elastic rebound

- Structural integrity

This is why silicone is often chosen for medical and wearable applications where long-term reliability matters.

Long-Term Experience Matters More Than First Impressions

TPE often wins on first impression. Silicone wins on consistency.

For users who value durability, hygiene, and predictable performance over time, understanding how materials age is just as important as how they feel on day one.

Material degradation isn’t a defect — it’s a characteristic. The key is choosing the right material for the experience you want to maintain.